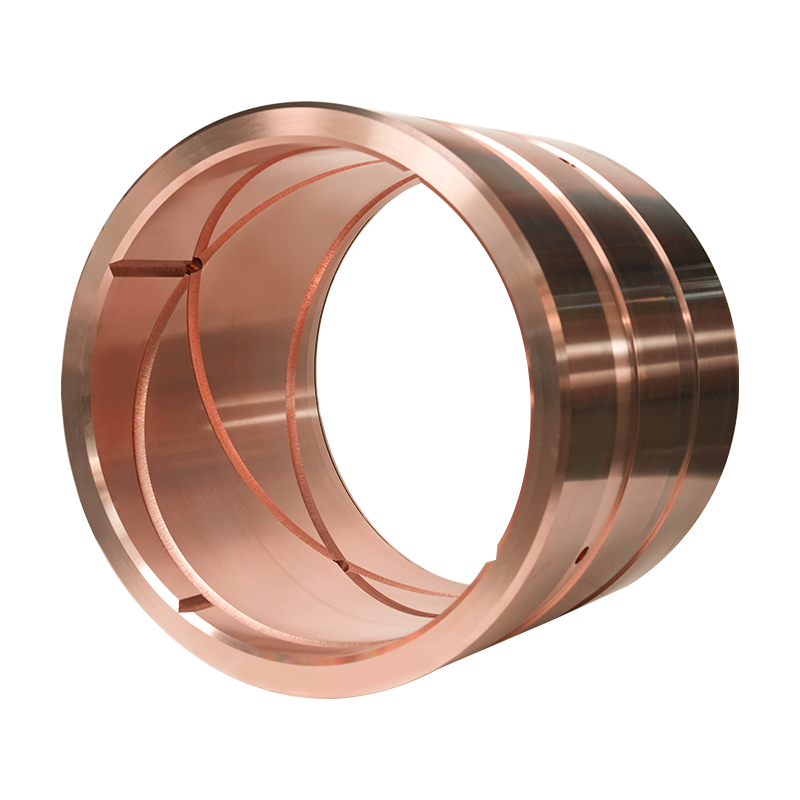

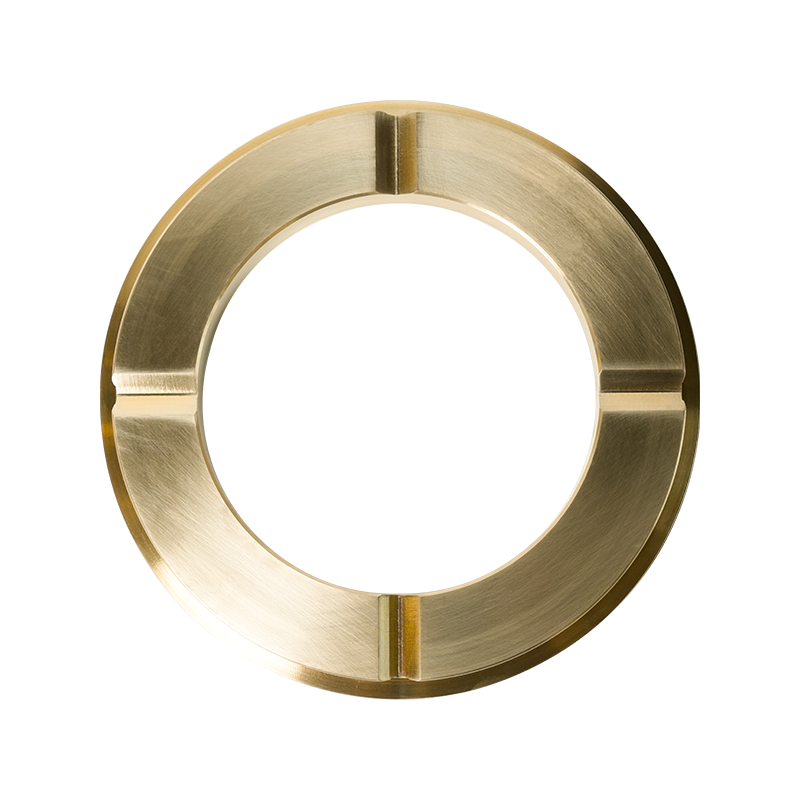

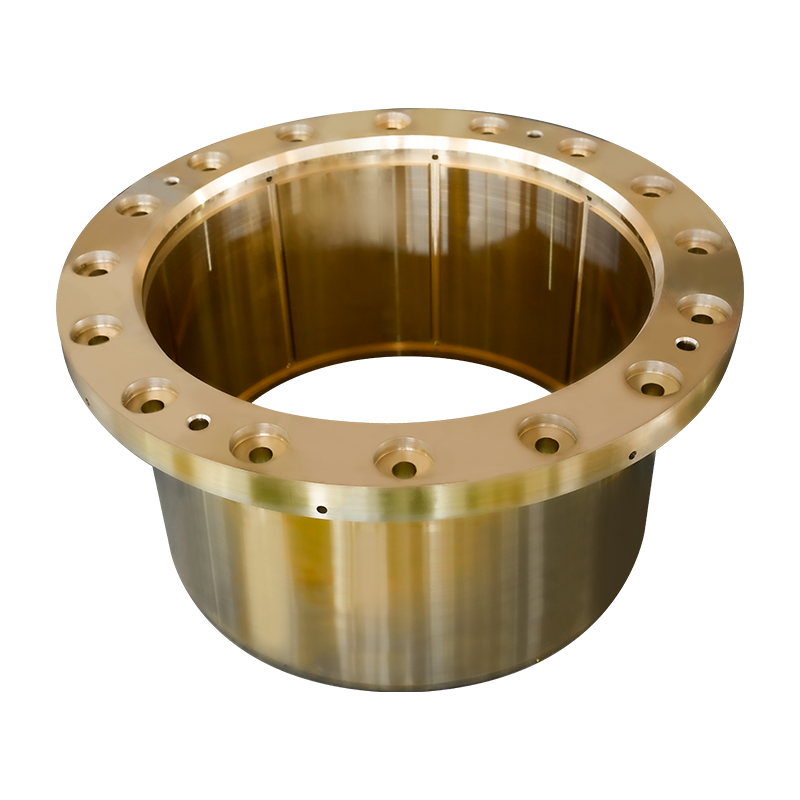

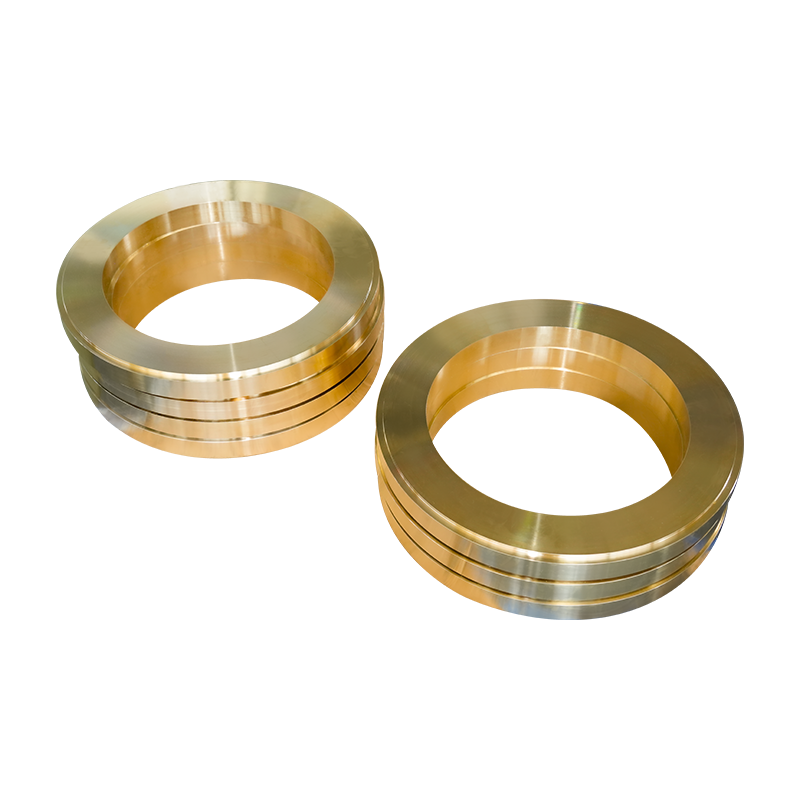

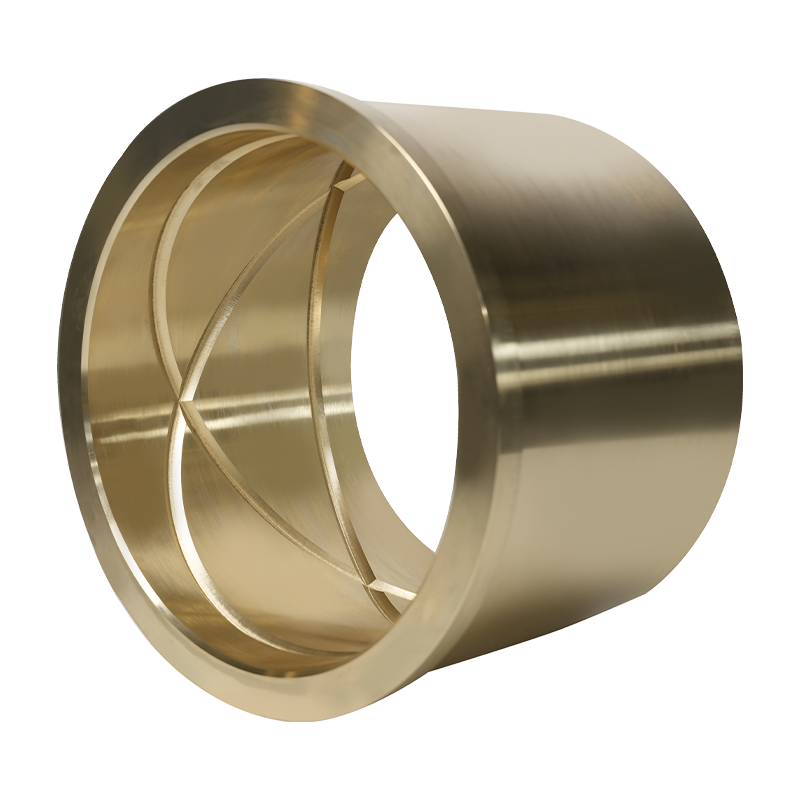

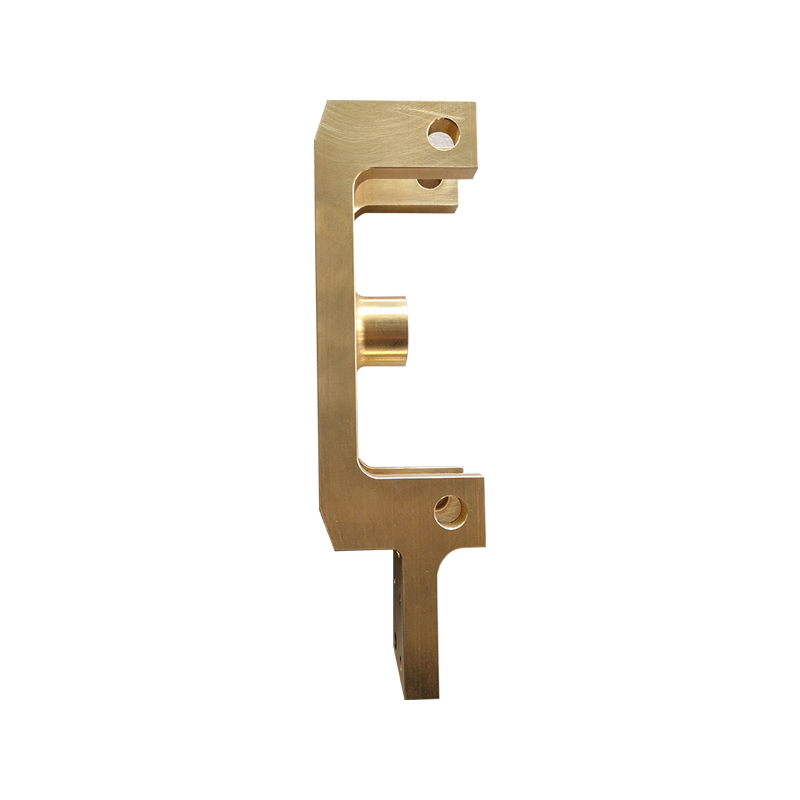

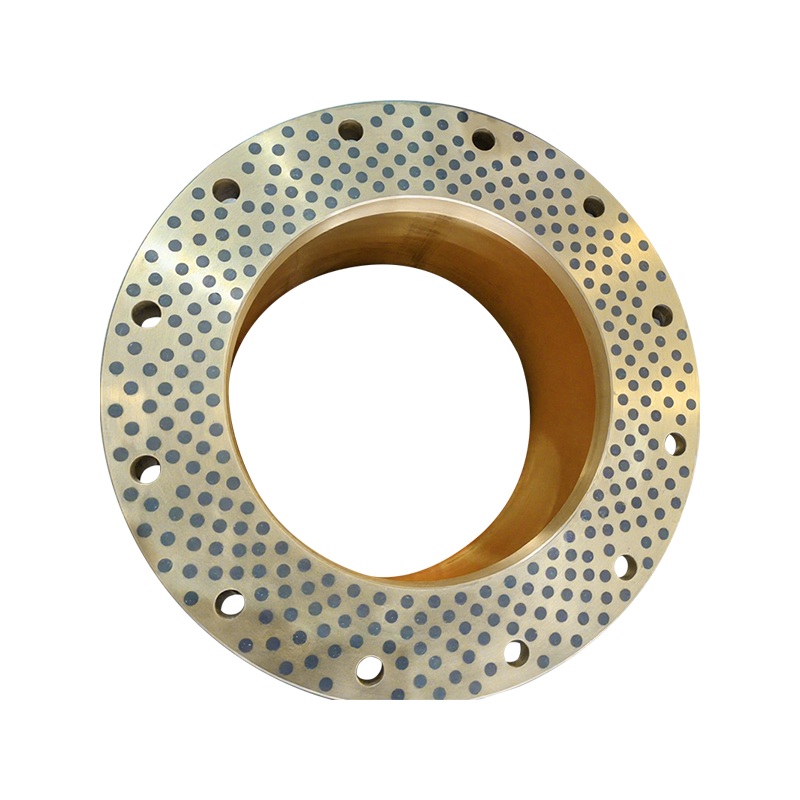

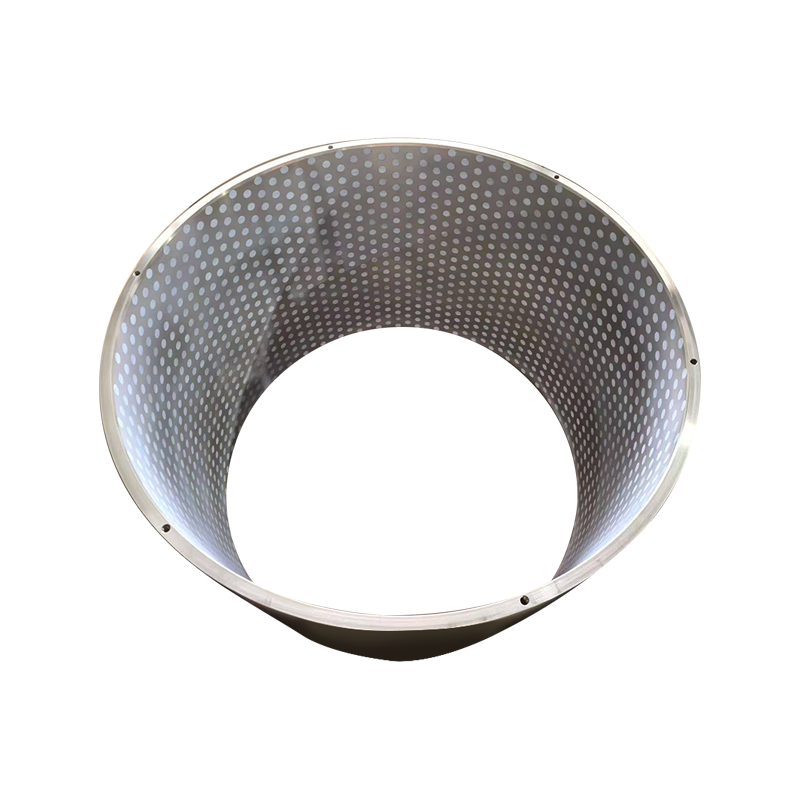

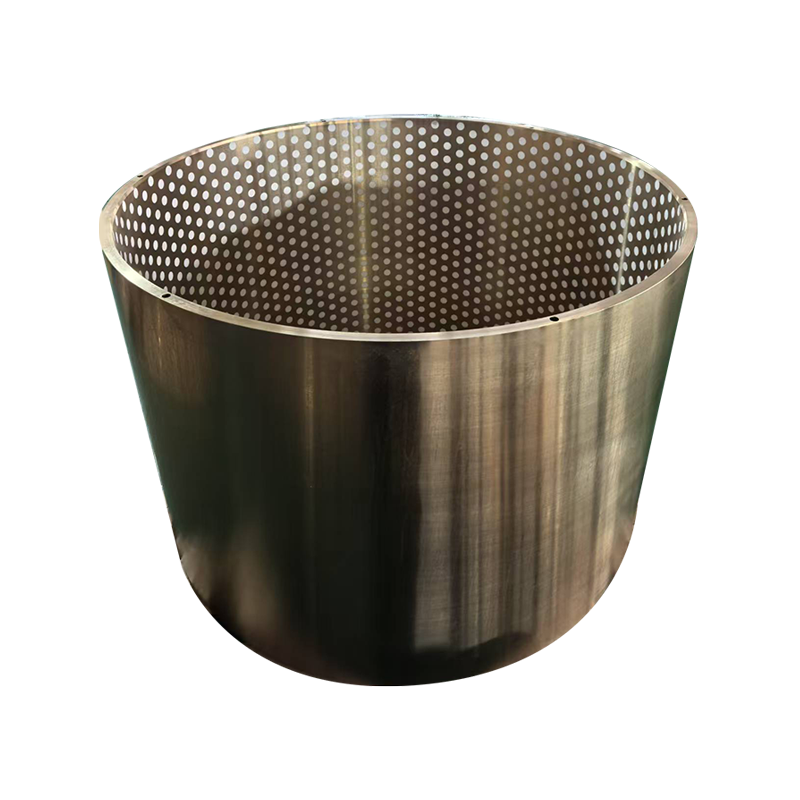

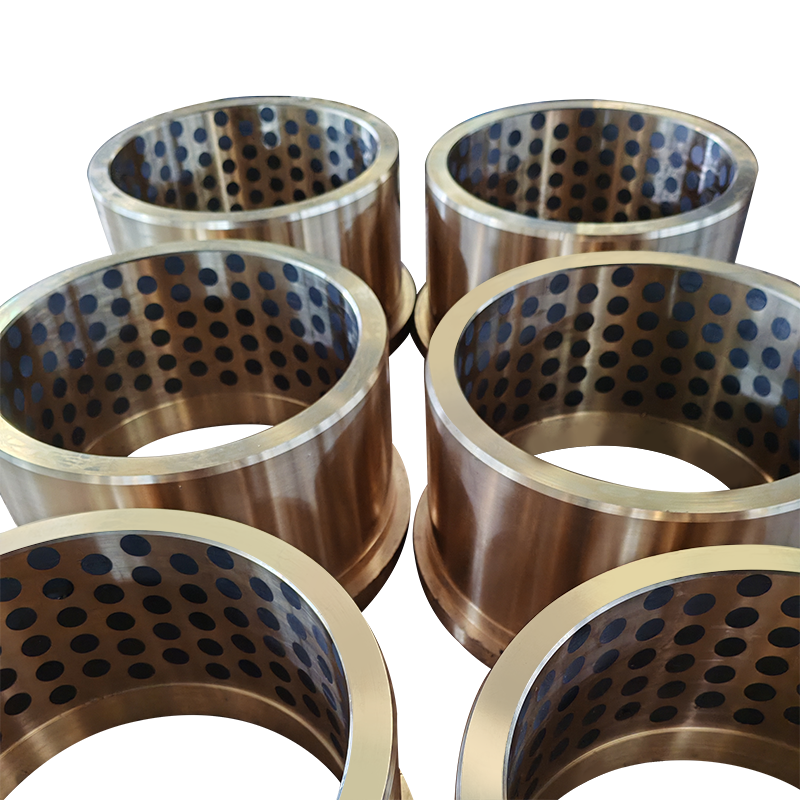

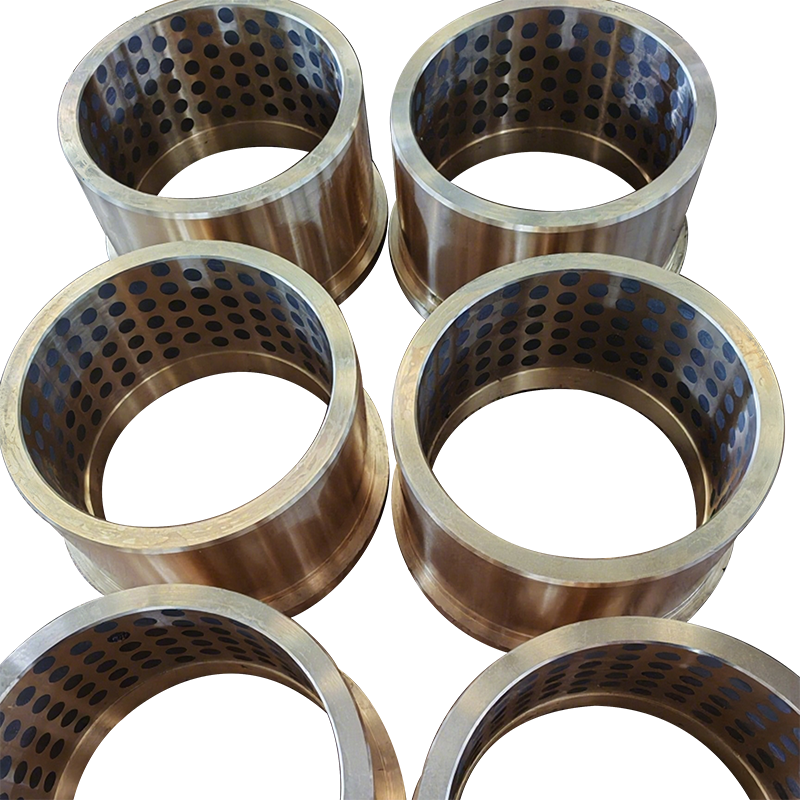

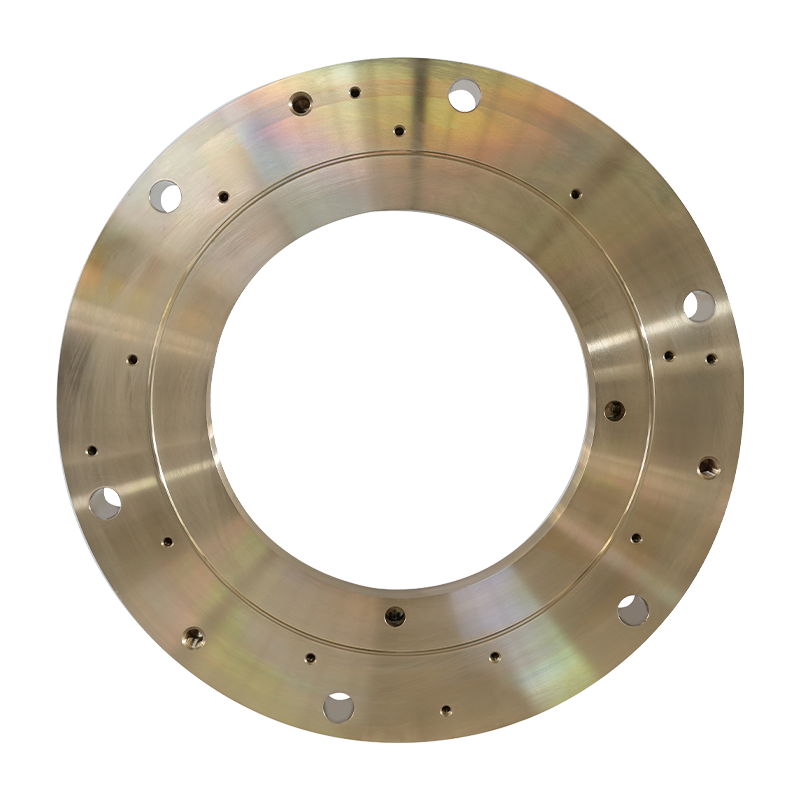

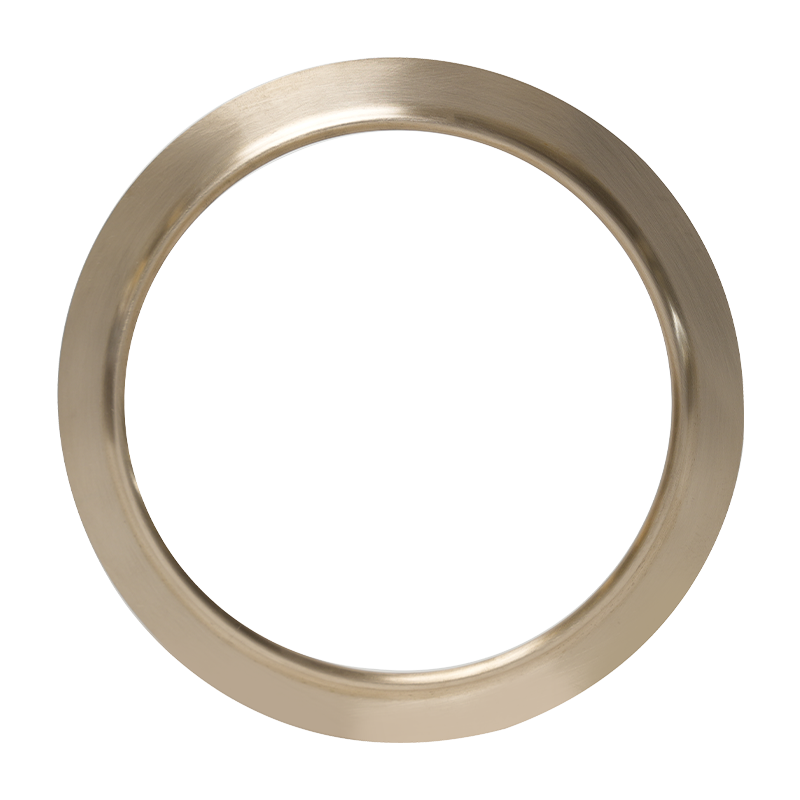

In der anspruchsvollen Welt der Mineraliengewinnung und -verarbeitung tragen die kleinsten Komponenten oft die größten Belastungen. Von den massiven Backen eines Steinbrechers bis hin zum unerbittlichen Zug eines kilometerlangen Förderbandes – Bergbaubetriebe sind auf ein empfindliches Gleichgewicht aus Kraft und Präzision angewiesen. In letzter Zeit stellten Branchenexperten und Wartungsmanager eine zentrale Frage: Wie können wir die Lebensdauer unserer schweren Maschinen verlängern, ohne unsere Wartungsbudgets in die Höhe zu treiben? Die Antwort führt häufig auf eine kritische, wenn auch bescheidene Komponente zurück: die Messingbuchse für Bergbauausrüstung . Auch wenn sie vielleicht nicht den optischen Eindruck eines riesigen Baggers oder den High-Tech-Anspruch einer automatisierten Bohrsoftware hat, revolutioniert diese spezielle Hardware derzeit die Art und Weise, wie Bergbaustandorte mit Verschleiß umgehen. Das unsichtbare Rückgrat der Mine Um zu verstehen, warum Menschen über Messingbuchsen sprechen, müssen wir zunächst die Umgebung verstehen, in der sie leben. Eine Mine ist ein feindseliger Ort für Maschinen. Es ist mit abrasivem Staub, extremem Druck und ständigen Vibrationen gefüllt. Unter diesen Bedingungen „verschleißen“ bewegliche Teile nicht einfach – sie können katastrophal ausfallen, wenn sie nicht geschützt werden. Eine Buchse fungiert als Opferschnittstelle zwischen zwei beweglichen Teilen. Anstatt dass zwei teure Stahlwellen aneinander schleifen, wird eine Messingbuchse dazwischen platziert. Es nimmt die Hauptreibung auf, absorbiert die Hitze und sorgt dafür, dass die „großen“ Teile der Maschine unbeschädigt bleiben. Warum Messing? Sie fragen sich vielleicht, warum wir Messing anstelle von Stahl oder Kunststoff verwenden. Die „Messingbuchse für Bergbauausrüstung“ wurde speziell für entwickelt Bedingungen mit hoher Belastung und hohem Verschleiß . Messing bietet eine einzigartige Kombination physikalischer Eigenschaften: Geringe Reibung: Es gleitet von Natur aus besser auf Stahl als Stahl auf sich selbst. Wärmeableitung: Es leitet die Wärme schnell von der Verbindung ab und verhindert so ein Festfressen. Hohe Festigkeit: Im Gegensatz zu weicheren Metallen kann hochwertiges Messing einem Druck von mehreren Tausend Pfund standhalten, ohne sich zu verformen. Beantwortung der häufigsten Fragen Während Bergbauunternehmen ihre Lieferketten optimieren möchten, sind mehrere häufig gestellte Fragen zu diesen Komponenten aufgetaucht. Lassen Sie uns die häufigsten Anfragen aufschlüsseln, die die aktuellen Markttrends bestimmen. 1. Können diese Buchsen „Stoßbelastungen“ standhalten? Eine der häufigsten Fragen von Brecherbetreibern ist, ob eine Messingbuchse einer „Stoßbelastung“ standhalten kann – dem Moment, in dem ein massiver, unzerbrechlicher Stein in den Brecher eindringt und einen Stoß durch das gesamte System sendet. Da diese Buchsen aus hochfesten Messingmaterialien bestehen, verfügen sie über ein Maß an Widerstandsfähigkeit, das spröden Materialien fehlt. Sie wirken als Polster. Während eine Hülse aus Keramik oder gehärtetem Stahl bei einem plötzlichen Aufprall reißen kann, verfügt eine Messingbuchse über die strukturelle Integrität, um die Energie zu absorbieren und die Welle am Laufen zu halten. 2. Wie verbessern sie die Lebensdauer der Ausrüstung? Wartungsleiter fragen oft: „Erspare ich durch den Wechsel zu einer Premium-Messingbuchse über ein Jahr hinweg tatsächlich Geld?“ Die Antwort liegt darin Stabilität . Wenn sich eine Buchse ungleichmäßig abnutzt, entsteht „Spiel“ oder „Spiel“ in der Maschine. Diese Vibration breitet sich dann durch die Leitung aus und beschädigt Dichtungen, Getriebe und Motoren. Durch die Verwendung einer speziell auf Druckfestigkeit ausgelegten Buchse bleibt die Ausrüstung länger perfekt ausgerichtet. Dadurch wird nicht nur die Buchse geschont; es schont die gesamte Maschine. Anwendungen im gesamten Bergbaulebenszyklus Die Vielseitigkeit des Messingbuchse für Bergbauausrüstung Deshalb kommt es in fast jeder Phase des Bergbauprozesses vor. Hier entfalten diese Komponenten heute den größten Einfluss: Brecher und Pulverisierer In der Zerkleinerungsphase arbeiten die Geräte mit niedrigen bis mittleren Geschwindigkeiten, aber unter enormem Gewicht. Dabei ist die Druckfestigkeit von hochwertigem Messing entscheidend. Ob Backenbrecher, Kegelbrecher oder Kreiselbrecher, die Buchsen sorgen dafür, dass sich die Exzenterwellen unter dem Gewicht von mehreren Tonnen Erz reibungslos drehen können. Fördersysteme Förderer sind die Adern eines Bergwerks, die rund um die Uhr Material transportieren. Die Rollen und Riemenscheiben in diesen Systemen unterliegen einem Reibungsverlust. Durch den Einsatz von Messinghülsen können Unternehmen den Energieaufwand für die Bewegung der Bänder reduzieren, was zu geringeren Stromkosten und weniger Bandrissen durch „eingefrorene“ Rollen führt. Mineralverarbeitungsausrüstung Sobald das Erz zerkleinert ist, gelangt es in Vibrationssiebe und Flotationszellen. Diese Maschinen arbeiten in nassen, oft chemisch aggressiven Umgebungen. Die Korrosionsbeständigkeit von Messing macht es zur idealen Wahl für diese Szenarien und stellt sicher, dass die Buchsen nicht rosten oder festfressen, wenn sie Feuchtigkeit ausgesetzt werden. Die wirtschaftlichen Auswirkungen hochwertiger Materialien In der aktuellen Weltwirtschaft ist der „billigste“ Teil selten der kostengünstigste. Bergbauunternehmen verabschieden sich von allgemeiner Hardware und setzen auf spezialisierte Komponenten. Funktion Auswirkungen auf den Betrieb Langfristiger Nutzen Hohe Festigkeit Unterstützt schwerere Erzladungen Erhöht den täglichen Durchsatz Verschleißfestigkeit Kürzere Austauschintervalle Reduzierte Arbeitskosten Druckfestigkeit Behält die Ausrichtung bei Verhindert katastrophale Motorausfälle Reduzierte Reibung Geringere Wärmeentwicklung Spart Schmierstoff und Energie Reibungsverluste reduzieren Reibung ist der stille Dieb der Bergbauindustrie. Es verbraucht Kraftstoff, erzeugt Hitze, die Schmiermittel zerstört, und dünnt Metallteile aus. Die „spezielle Konstruktion“ dieser Messingbuchsen zielt darauf ab, diesen Verlust zu minimieren. Wenn die Reibung reduziert wird, muss der Motor nicht so stark arbeiten, was die Leistung erheblich verbessert Betriebsstabilität der gesamten Anlage. Worauf sollten Sie achten? Worauf sollten Sie achten, wenn Sie Beschaffungsbeauftragter oder Bauingenieur sind? Messingbuchse für Bergbauausrüstung ? Suchen Sie zunächst nach materielle Reinheit . Minderwertiges Messing enthält häufig Verunreinigungen, die zu „weichen Stellen“ in der Buchse führen und zu einem vorzeitigen Ausfall führen können. Hochwertiges Messing sollte eine gleichmäßige Kornstruktur aufweisen. Zweitens, bedenken Sie die Belastbarkeit . Nicht jedes Messing ist gleich. Für den Bergbau benötigen Sie ein Material, das für den „Hochlastbetrieb“ ausgelegt ist. Dies bedeutet, dass die Legierung speziell darauf abgestimmt wurde, sowohl die Härte zu bieten, die zur Widerstandsfähigkeit gegen Verschleiß erforderlich ist, als auch die Duktilität, die zur Bewältigung von Druck erforderlich ist. Die Zukunft der Bergbauwartung Während wir uns dem „Bergbau 4.0“ nähern, bei dem Sensoren jede Bewegung einer Maschine überwachen, bestätigen die Daten, was Old-School-Mechaniker seit Jahrzehnten wissen: Die Qualität Ihrer Verschleißteile bestimmt den Erfolg Ihrer Saison. Moderne Sensoren können nun genau erkennen, wann eine Buchse dünner wird. Durch den Einsatz von High-End Messingbuchse für Bergbauausrüstungs stellen Betreiber fest, dass ihre „Alarmprotokolle“ viel leiser sind. Die Anlage läuft ruhiger, bleibt kühler und erfordert weniger Notabschaltungen. Fazit: Eine kleine Investition für eine enorme Rendite Die Diskussion über die Effizienz des Bergbaus verändert sich. Es kommt nicht mehr nur auf die Größe des LKWs oder die Leistung der Bohrmaschine an; Es geht um die Zuverlässigkeit der Verbindungen, die sie zusammenhalten. Durch die Auswahl von Komponenten, die für die spezifischen Anforderungen der Branche ausgelegt sind – hohe Festigkeit, Druckfestigkeit und Belastbarkeit bei niedriger Geschwindigkeit – sichern Bergbaubetriebe ihre Zukunft. Die Messingbuchse für Bergbauausrüstung ist mehr als nur ein Stück Metall; Es ist ein Schutz für Ihre wertvollsten Vermögenswerte. Können Sie es sich in einer Branche, in der jede Minute Ausfallzeit Tausende von Dollar kostet, leisten, etwas weniger als das Beste zu verwenden?

Mehr lesen

English

English 日本語

日本語 русский

русский Deutsch

Deutsch